Carbon Black

- Home

- Carbon Black

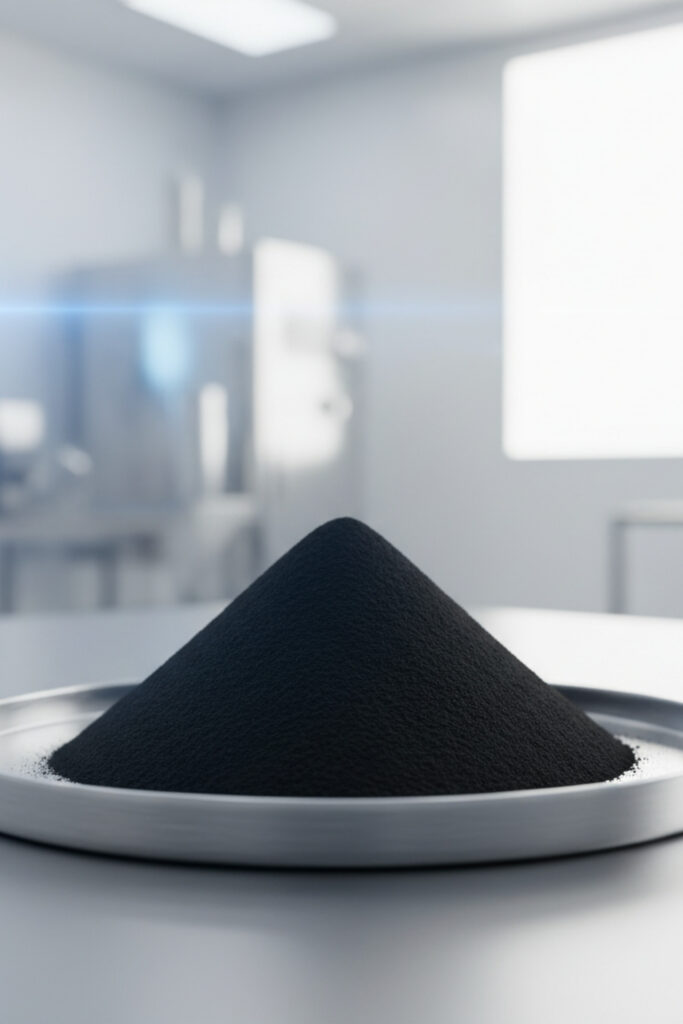

Embrace Sustainability with Recovered Carbon Black (rCB)

Gravita is driving the shift toward sustainable materials by transforming waste tyres into high-performance Recovered Carbon Black (rCB). Our advanced recycling process minimizes emissions, supports circular economy practices, and offers a cost-effective solution for manufacturers seeking eco-efficient materials.

Recovered Carbon Black is produced from end-of-life tyres using modern pyrolysis and refining technology. Unlike conventional carbon black production, which consumes large amounts of fossil fuels and water while generating high CO₂ emissions, our rCB provides a sustainable alternative without compromising quality or performance.

At Gravita, we ensure consistent quality and performance by maintaining full control over our feedstock selection and using a continuous pyrolysis process. This allows us to deliver uniform carbon structure, stable properties, and reliable output for diverse industrial applications.

Key Benefits

High Purity: Our advanced demineralization process ensures low ash content and high surface activity, producing nearly ash-free recovered carbon black (rCB). This makes it ideal for demanding applications across tyre manufacturing, rubber products, plastic colorants, and the color and pigment industry.

Sustainable: Replaces the need for virgin carbon black, conserving natural resources and reducing landfill waste.

Versatile Applications: Used in Tyres, rubber goods, plastics, coatings and as a pigment in various industries.

High-Performance Virgin CB Alternative: Our product consistently delivers the quality required for demanding industrial applications, offering a reliable substitute for virgin carbon black.

Reduced Carbon Footprint: Choosing our carbon black helps lower overall CO₂ emissions by decreasing the dependence on carbon black derived from fossil fuels.

Fosters Circular Economy: Our process actively supports the principles of a circular economy by converting end-of-life Tyres into valuable and sustainable resources.

Established Performance in Rubber & Plastics: Our product is trusted and utilized by leading manufacturers globally in both rubber and plastics industries.

Applications

Tyre manufacturing

Rubber and plastic products

Industrial colorants and masterbatches

- Building materials and coatings

Send Your Inquiry

Connect with us today to learn more.

Connect with our team today

FAQ's

It is a high-quality carbon material derived from recycled tyres, used as a sustainable replacement for virgin carbon black.

rCB is used in tyres, rubber products, plastics, coatings, inks, and pigments.

Our advanced demineralization and refining process ensures low ash content and high surface activity.

Using rCB lowers CO₂ output by reducing dependence on carbon black produced from fossil fuels.

Yes, it offers a lower-cost, sustainable alternative with comparable performance to virgin carbon black.

Yes, we provide detailed TDS and sample material for evaluation upon request.